Calling all Engineers

Super-powering engineers to generate rather than draft designs

With the pace of change in the world, engineering is under increasing pressure to produce complex and high-performing products faster than ever. Physical goods today are typically manually drafted in CAD and then re-drafted whenever detail is added, a trade-off is needed, new information comes in, requirements change, or an issue is found. It’s a constant battle to keep up. Iterating manually in response to these changes creates bottlenecks and slows down design reviews, leading to decisions that rely primarily on the valuable intuition of experienced engineers.

This paradigm of manual iteration does eventually work. It’s trusted in engineering industries where bad design decisions can cause death, where strict regulations need to be met before any product can be used, and where expensive machinery and supply chains are needed for manufacturing.

Yet, to meet humanity’s most pressing problems, our world needs re-engineering with novel solutions made from novel materials that push the limits of past experience. This creates an immense space of design possibilities for engineers to navigate, but also creates a huge opportunity for engineering.

A new paradigm of iterating on designs is needed: one where designs are generated rather than drafted, where an engineer's intuition is superpowered by exploring many more possibilities, and where the whole team is able to make efficient and collaborative decisions in a fraction of the time.

From drafted to generated design

Manual drafting involves humans directly manipulating designs in CAD tools like SolidWorks, Siemens NX, or AutoCAD. Each design must be created by hand, one at a time. When designs are generated instead, engineers control high-level parameters and let the design details (geometry and otherwise) be created automatically.

You might have heard about or experimented with methods like:

Topology optimization (what the term “generative design” in engineering often refers to).

Computational engineering, through visual programming or writing code.

Optimisation and exploration algorithms (like those in process integration and design optimization tools)

Methods like this let engineers work where they are strongest: handling complex trade-offs and inventing solutions, rather than repetitive tasks managing low-level details.

While these methods show incredible promise, they haven’t realised their potential due to the lack of supporting infrastructure for seamless integration into organisations. As modern engineering systems grow more complex, real-world engineering remains unpredictable — and deeply human. The challenge lies in bridging the gap between sophisticated methods and the realities of messy, human-driven processes.

Engineering is increasingly complex

With new technologies, such as additive manufacturing, complexity is only increasing: compare a simple bracket designed for sheet metal to one designed for additive manufacturing from novel materials.

Now imagine the increase in complexity when these new technologies are introduced to systems like cars, buildings, wind farms, infrastructure and everything else the future demands. This complexity makes manual iteration responsible for weeks, months or even years of delays: manually changing all aspects of a highly complex system is laborious, prone to error, and makes it hard to predict the knock-on effect of propagating changes.

Some tools of today see the pain of this complexity and try to manage it: requirements management tools, product data management (PDM) tools, bill-of-material (BOM) spreadsheets etc. Yet they are built for a single-design world and assume that a human should work at the level of complexity of the engineering system directly.

Irrespective of how good they are (ask around and you’ll see that they are not engineers’ favourite tools), this central assumption inherently calls for more data management as physical products get more complex, rather than less.

To keep engineers doing engineering, the assumption that a human works at the level of complexity of the system needs to change, and the tools built for this assumption need to be replaced.

Engineering is Human

Engineering complex products requires a team of people with a wide variety of expertise: product managers, business stakeholders, mechanical engineers, electrical engineers, aerodynamics engineers, simulation teams, clients, suppliers, part vendors, and more. All of these need to come together to align on the design of high-performing, low-cost, manufacturable parts and systems.

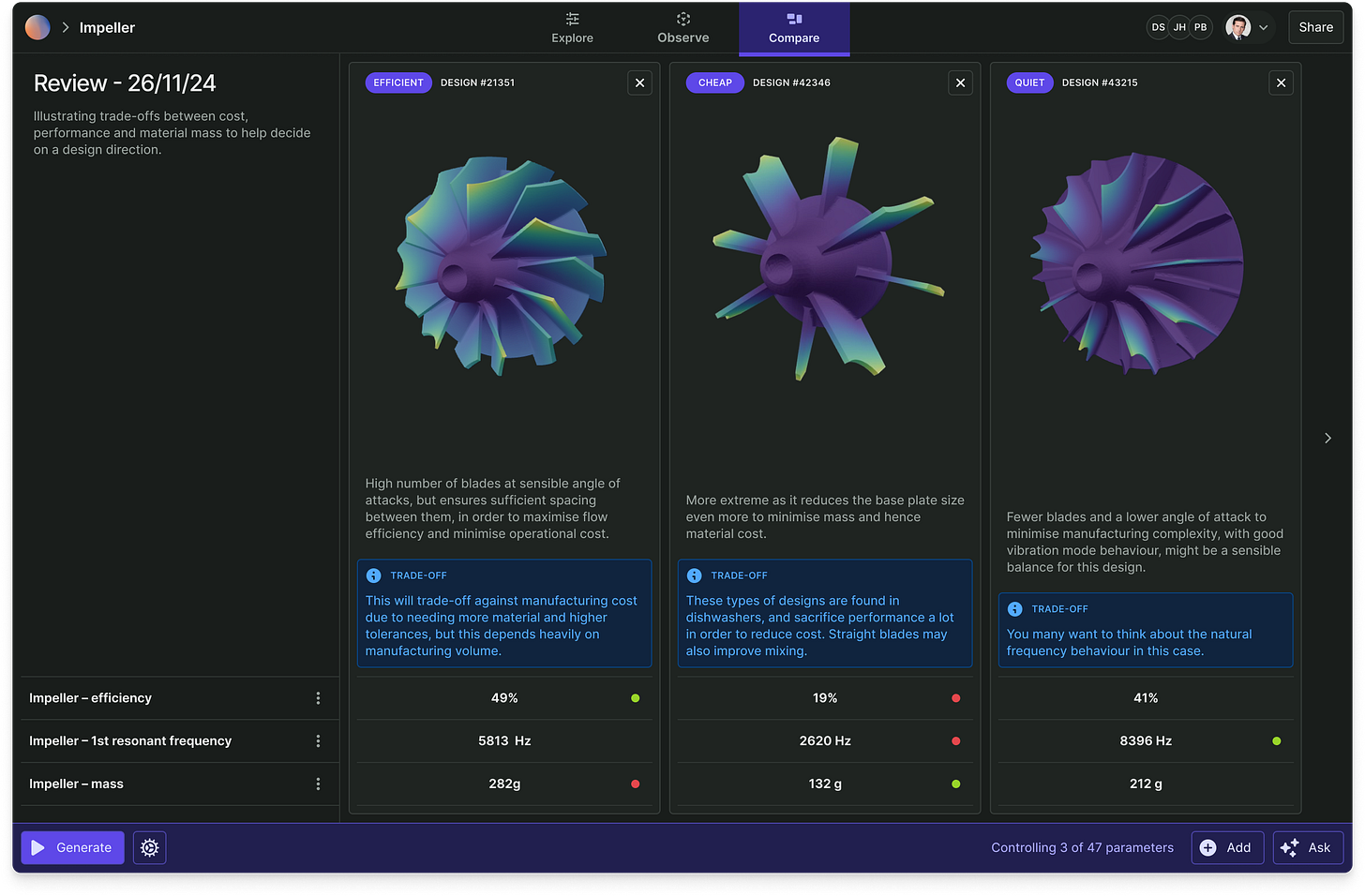

This means collaborative reviewing of design possibilities is central to the engineering design process. Today, engineers present a small number of manually created design possibilities to get reviews from many stakeholders with many conflicting goals. This then requires hard trade-offs to be made collectively, without enough data to realistically know the right direction. So engineers rely on intuition gained from experience, and the most experienced (or loudest) voice in the room usually wins. Then the original engineer goes away to manually redesign their component based on this feedback.

When a small variation on an existing product is being designed, this intuition might be good enough. When designing novel engineering products, making decisions without enough data leads to years of delays.

Quantity as the driver of quality

Most generative software tools let engineers create a so-called “optimal” design that meets their high-level targets. This leads to comparisons such as “the generated design ended up 12% cheaper and 20% lighter than the manually created one”. Such comparisons with traditional methods, while already beneficial, miss out on some key advantages:

You can generate many design options at once - for a similar cost & time to creating one.

You can re-generate when the high-level requirements change, without manual iteration.

With these, considering trade-offs becomes instantaneous. Today engineers manually explore different options, analyse each one, and present trade-offs in design reviews. Tomorrow the design review is where all trade-offs can be made in real-time — as easy as generating a single design.

Anyone can generate new options by simply updating high level parameters, making it easier for teams to respond to changing needs and requirements. The engineers avoid having to work directly with the low-level & complex detail.

The set of generated designs can then be used as the basis for the next iteration, giving a paradigm of iteration based on repeated generation of many designs rather than repeated manual changes of one design.

Imagine every question asked by a product manager, engineering expert, or customer being instantly answered by a clear impact: “improving the performance by 11% would increase manufacturing costs by 8%, shall we continue?”. How much faster could engineering systems be brought to market?

The potential of this paradigm to improve how engineering products are designed is large, but just having the ability for one engineer to generate is not enough. The rest of the process of engineering design has to improve with it for this potential to be realised.

Empowering engineering organisations today

It’s a journey driven by a thriving community. Companies like nTop, Synera, Simscale, Leap71, Hyperganic, ToffeeX, Zoo, and Grasshopper are empowering innovative engineers to generate and test designs in remarkable new ways.

But these innovators often face scepticism from colleagues and suppliers, who find it hard to manage and trust the many generated design options. On top of that, integrating generative work into their organisation’s data and project management processes can quickly turn into a nightmare.

It’s time to change that—we're out to support innovative engineers that want to transform existing manual engineering into generative engineering, for the whole team, one step at a time, with engineering software fit for challenges of the next century.

We are calling out to all of these innovators: Generative Engineering’s technology is now available for early access. The engineering industry needs your input to test, criticise, and enable what we perceive as the future of engineering design. We do not believe in replacing engineers with software, we believe new software will enable engineers to use their expertise to start building tomorrow's products, today.

For early access to what we’re building…

Or reach out at helloworld@generative.vision.